Test introduction BS476-7

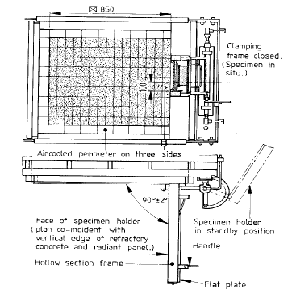

This Part of BS 476 specifies a method of test for measuring the lateral spread of flame along the surface of a specimen of a product orientated in the vertical position under opposed flow conditions, and a classification system based on the rate and extent of the spread of flame. It provides data suitable for comparing the end-use performances of essentially flat materials, composites or assemblies, which are used primarily as the exposed surfaces of walls or ceilings.

Test sample:

A minimum of six and a maximum of nine test specimens shall be provided, and they shall be representative of the exposed surface of the product.

Size of specimens: Except where the specimens are expected to achieve a class 1 standard, the specimens shall be rectangular and 885 mm *270 mm. Only where specimens are being prepared with a view to achieving a class 1 standard of performance, shall the length of the specimen be reduced to a minimum of 250 mm.

All specimens shall be tested at full thickness providing they fit into the specimen holder. If the product is of such a thickness that it will not fit into the specimen holder, its thickness shall be reduced by cutting away the unexposed face of the product to reduce the thickness to a minimum of 50 mm.

Test procedure:

1) Make adjustments to the gas-air supply to the apparatus and/or minor adjustments, within a tolerance of ± 2°, to the 90° angle formed between the specimen holder and the radiation panel surface to enable the required irradiances to be achieved.

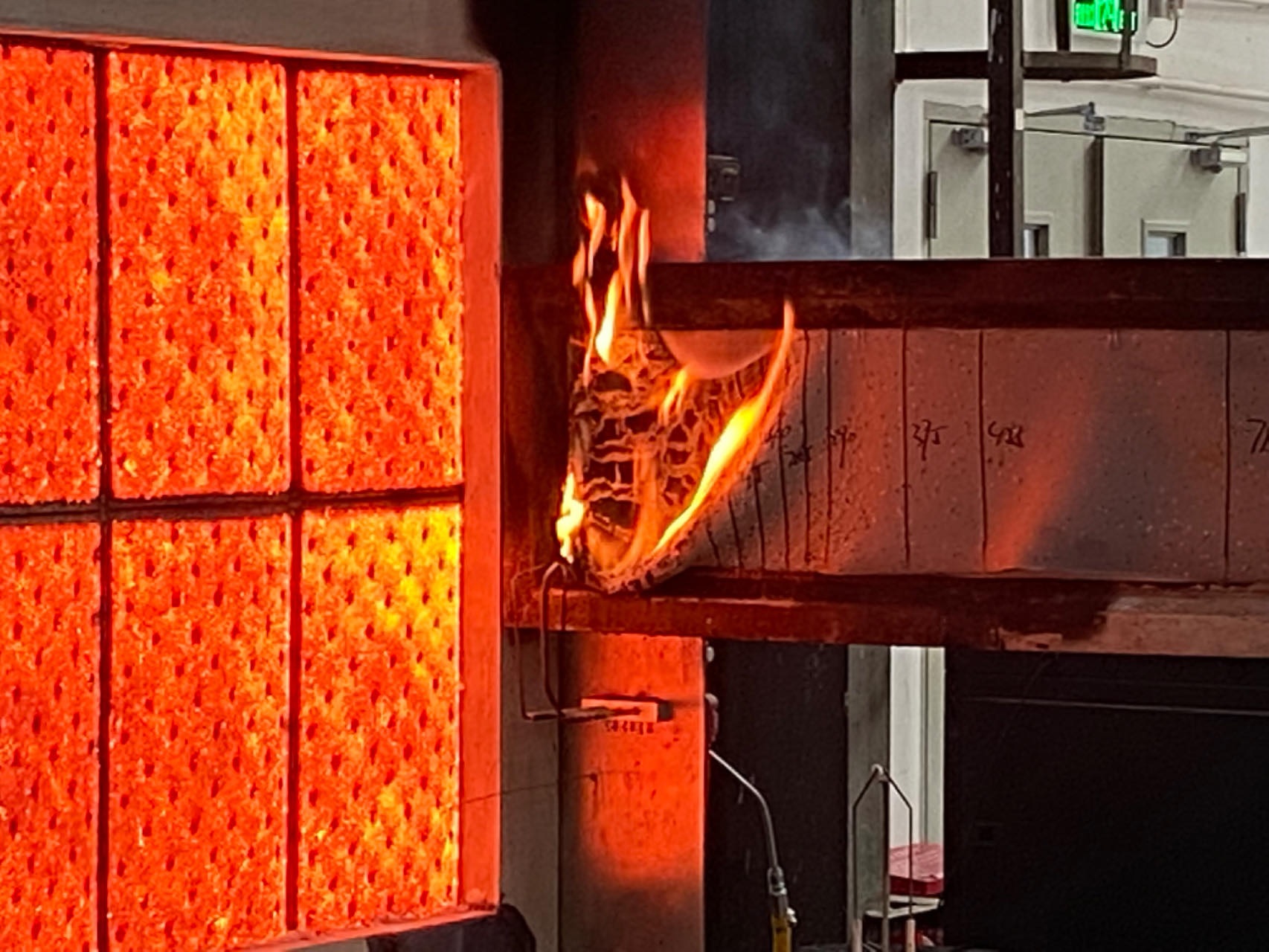

2) Ignite the pilot flame.

3) Remove a specimen construction, including any backing boards, spacers and filler pieces, from the conditioning atmosphere, and within 5 min insert it into the specimen holder in its standby position at 90°or more from the test position.

4) Within 5s swing the specimen holder and specimen into the test position, and immediately start the timing mechanism, i.e. start the test.

5) Extinguish the pilot flame 1 min after the start of the test.

6) Terminate the test when the flame front reaches the 825 mm reference line, or after 10 min has elapsed, whichever is the shorter.

7) Swing the specimen holder into its standby position and remove the remains of the specimen construction. Clean any debris from the holder.

8) Repeat the procedures given in 1) to 7) above for each of the remaining specimen constructions.

Recording of results

For each of the specimens tested, the following shall be recorded:

a) the time at which the flame front crosses each vertical reference line;

b) the maximum extent of spread of flame during the first 1.5 min from the start of the test;

c) the maximum extent of spread of flame during the whole test, i.e. 10 min or less;

d) the time and distance at which maximum spread of flame is reached;

e) any spread of flame that extends for less than 50 mm whilst the pilot flame is still on as `less than 50 mm'.

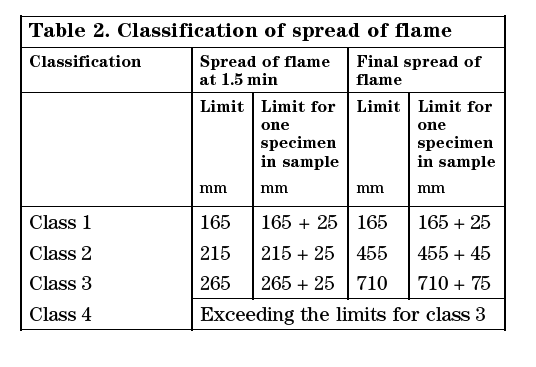

Classification of results:

The results recorded in above shall be used to obtain a classification for the product according to the criteria specified in table 2. At least five of the six test specimens for which valid test results have been obtained shall have a spread of flame which does not exceed the 1.5 min limit and the final limit specified for the designated class.

The remaining specimen shall not exceed this limit by more than the tolerances given in table 2.